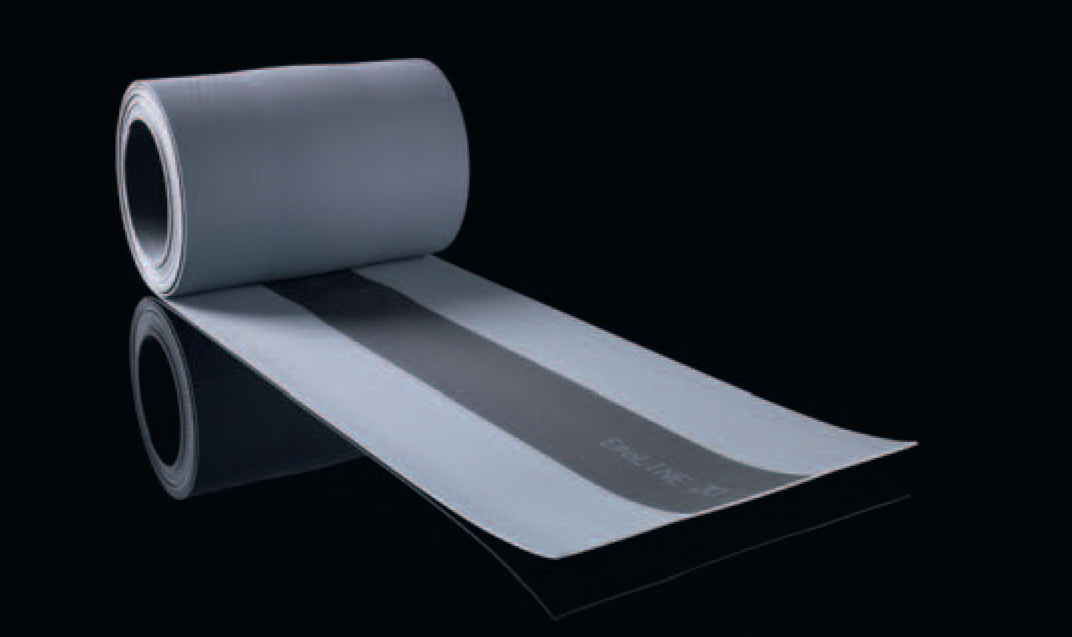

The expansion strip system for installation using epoxy.

Construction elements on buildings are exposed to constant forceful stress such as temperature fluctuations, earthquakes or other physical events. These have an effect on the volume and properties of the substances used and the construction materials, and can lead to fatigue symptoms or fractures which may have disastrous consequences. To prevent this, Soba Inter AG provides high-quality solutions for a long-lasting quality construction.

EpoLINE® is an expansion strip made of rubber. It is used to bridge three-dimensional joint movements between building parts that are subject to expansion. Pre-fabricated according to the sizes of the particular building elements, this strip system enables fast, secure placing of joint sealing.

System

EpoLINE® consists of an elastic part and two lateral adhesive flanges. These are permanently glued in using epoxy resin adhesive. This design separates the two functions, “Absorption of movement and expansion” and “Bonding to the epoxy adhesive”.

EpoLINE® expansion strips are usually pre-packaged with all the moulded parts for the particular building. For installations in several stages, or for very long building joints, which make the handling more difficult, the preparation can also be done on the building site using the vulcanisation machine that has been specially developed for this purpose. Contact our technical service directly to find out about the available options.

Advantages of EpoLINE ®

- Economical installation thanks to prefabricated, precisely fitting expansion joint strips

- Strips and moulded parts are supplied as pre-packaged systems

- The “Sandwich design” means no complicated sub-structure is needed

- Very good resistance to building oscillations ( e.g. during earthquakes)

- Flat construction without any kinks or bumps

- Easily follows the line of every joint

- Highly elastic expansion zone

- Force-fit connections on bitumen or using epoxy adhesive on concrete and metal, etc.

- Special metal connecting pieces for joins on sheet metal work

- The individual strips can be joined together on the building site using the specially developed vulcanisation machine.